Item: EX10280397

|Model: WIE-PM-1200A

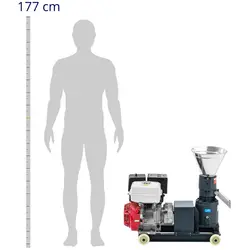

Pellet Machine - 60 - 100 kg/h - 7.5 HP - Ø 120 mm

Lowest price in the 30 days before the discount: €1,349.00

- Versatile – the pellet press produces pellets for feeding or fertilising

- Powerful – processes 60 - 100 kg/h of feed over 8 - 10 hours

- Forceful – 7.5 HP petrol engine delivers a speed of 1800 RPM

- Durable – long pellet lifespan of the pellets thanks to 60 to 80 °C heat treatment

- Intuitive – operating the animal feed pellet machine is effortless due to its compact, mobile design

Product Description

The pellet press rapidly yields large batches of feed sticks

Do you feed or fertilise with pellets? The Wiesenfield pellet press allows you to produce up to 100 kg of feed sticks per hour. And with an operating time of 8 - 10 hours, you can produce large quantities with ease.

Ideal for culinary innovators – the Wiesenfield animal feed press!

What should go into your fertiliser sticks and animal feed? It's up to you to decide which vitamins and minerals to add to maize, oats, or hay. But how does it work? Heat the pellet press for vacuum heat treatment to 60 to 80°C. This warming process ensures surfaces remain undamaged or deformed during heating. Next, add the material you wish to press. Two solid rollers push the contents through a die measuring 120 mm in diameter. The result: firmly compressed, durable pellets with a diameter of 6 mm. If you want to produce pellets with a different diameter, you will need different moulds.

Make use of the handy discharge chute to fill the finished pellets directly into sacks. The control interface is designed for clarity and ease of use. An emergency stop switch ensures safety. The pellet machine benefits from a powerful 7.5 HP petrol motor and is mobile atop 4 sturdy wheels.

Note: Make sure to include the pellet binder in your order (Product number: 10530000). The wheat starch powder makes it easier to press and store your pellets.

Note on wearing parts: You can use the built-in dies and rollers for pellet presses for up to 300 hours. If they are worn, replace them promptly. Wearing parts are not covered by warranty. Please contact expondo customer service for spare parts.