Metalworking is a set of techniques aimed at changing the shape of metal, as well as chemical or physical properties for practical use. In our article we shall provide an overview of the most popular method, as well as recommended tools.

Metalworking is a set of techniques aimed at changing the shape of metal, as well as chemical or physical properties for practical use. In our article we shall provide an overview of the most popular method, as well as recommended tools.

What is metalworking?

The historical roots of metalworking predate recorded history; its use spans cultures, civilisations and millennia, and initially it was about shaping soft, native metals like gold with simple hand tools, mainly for decorative purposes. It evolved into methods for smelting ores and hot forging of harder metals like iron, up to highly technical modern processes such as machining and welding. This was when people began to use various metals in the production of weapons and everyday products.

Over the millennia, technology has moved forward a great deal. Today there are many ways to precisely process metals in order to obtain the desired effect.

Metalworking processes

The main metalworking processes include: cutting, forming and joining. Digging deeper, there are many ways to connect metal elements with each other and various processes used for metal surfaces, which are designed to enhance their durability: protect them against corrosion or various acids, high temperatures, etc.

Below we present the most popular metalworking methods and techniques, which are currently widely used both in industry and crafts. Choosing the right one depends on the desired effect.

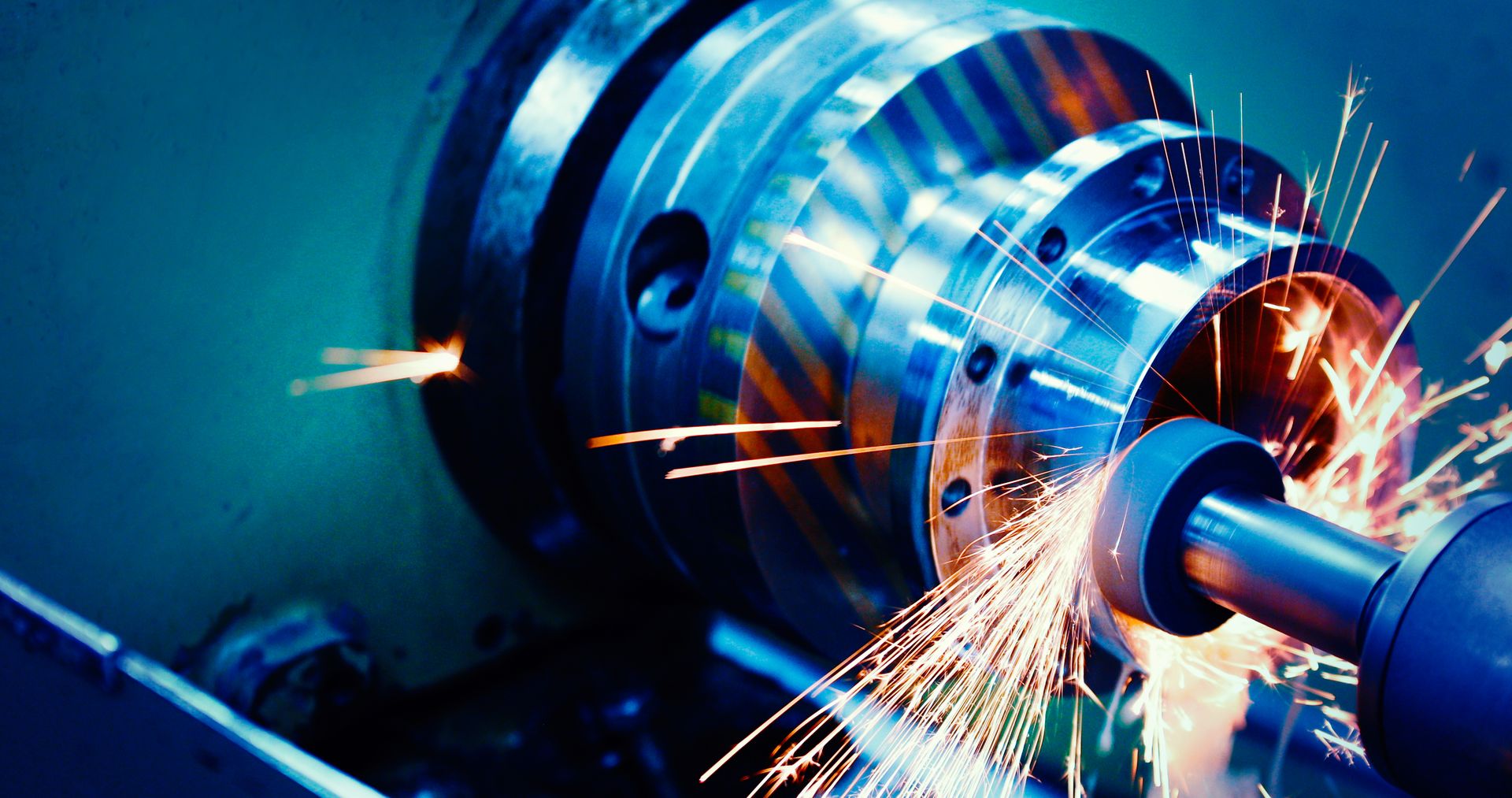

Milling

Milling is one of the many different methods of cutting metal. It is generally done on a milling machine, which is a power-driven machine with a milling cutter that rotates about the spindle axis, and a worktable that can move in multiple directions. This technique is divided, depending on the position of the blade, into frontal and circumferential, and depending on the location of the object – into counter-rotating and co-rotating.

Different cutters are used for the manufacture of tools and mechanical parts (gears, screws), as well as for making decorative shapes, grooves, etc.

Lathing

Lathing is another method of maching. It consists of separating, with the help of a blade, successive layers of the material most often put into rotation. Based on the position of the lathe blade in relation to the workpiece, external and internal lathing can be distinguished.

Lathes are used in many ways, e.g. in the production of mechanical parts (for cars and various types of machines), household items, sports accessories, etc. These machines are divided into speed, engine, turret, tool room and CNC lathes.

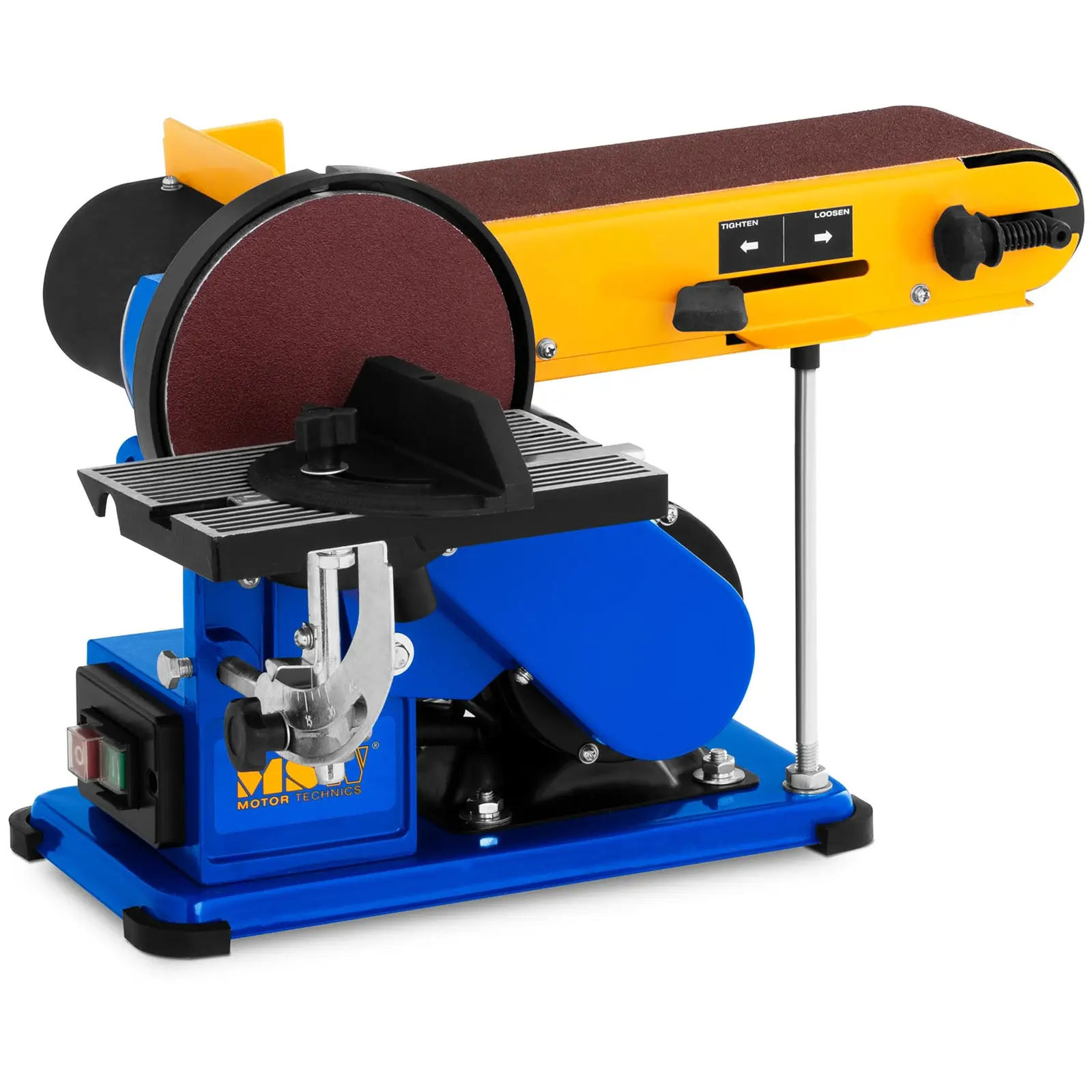

Grinding

This is another common method of metal processing. It consists in finishing the surface of metal elements with abrasive tools in order to give them a smooth form. A disc grinder, whetstone or abrasive tape can be used for this purpose. It is used to grind metal holes, shafts and planes.

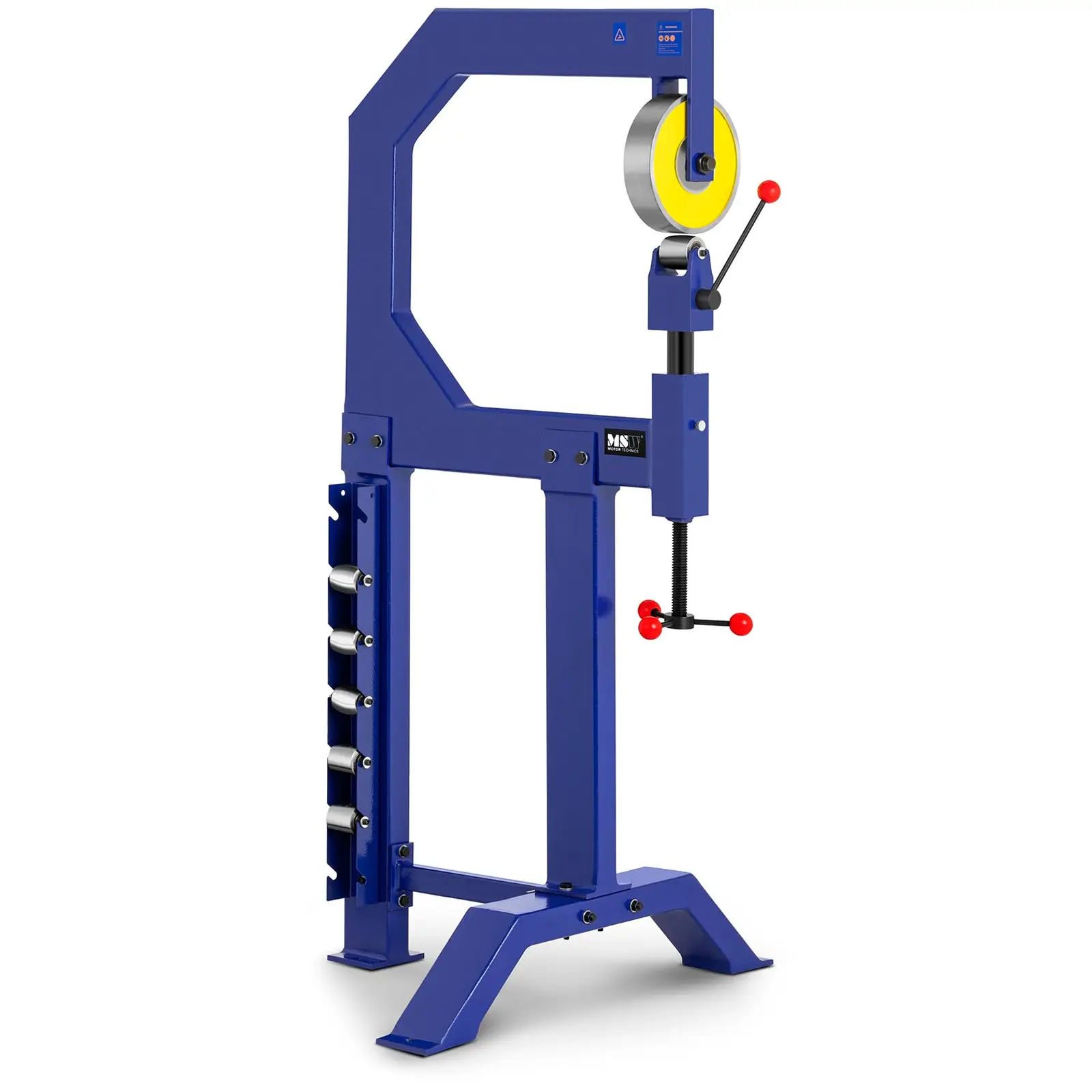

Forming

Forming refers to methods of processing metals by applying pressure on a given material in order to change the shape, dimensions, etc., and at the same time a change in the structure, and thus mechanical properties. Types of metal forming include, among others: rolling, forging, extrusion, drawing and stamping. Based on the working temperature, we can distinguish:

- hot working: carried out above the recrystallisation temperature of the metal,

- cold forming: metalworking processes below the recrystallisation temperature of the metal.

Cold forming improves the hardness and toughness of metal elements. They are also more brittle than those processed in high temperatures.

Heat treating

Heat treating is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. Heat treatment is commonly used for steel items. We can distinguish the following types of heat treating:

- Quenching: this process consists of heating the material to a specific temperature, keeping it at the temperature for a specified time, and then cooling it quickly.

- Annealing: this is similar to quenching, except that the metal is cooled slowly.

- Tempering: a previously quenched material is heated (often from approx. 150 to 650 °C), held for a while and then cooled down.

- Solutioning: a process similar to quenching used for stainless and acid-resistant steels.

- Heat hardening: quite a complicated technological process combining hardening with tempering, usually carried out at a temperature of approx. 500 °C.

- Stress relieving: a type of low temperature annealing (100-150 °C), which is applicable to relieving foundry stresses.

Sulfation

Sulfurisation is a chemical heat treating method for improving the sliding properties of metals. It is commonly used for bearings, cylinder liners, various types of shafts (including camshafts) and gears. It also helps enhance corrosion resistance, significantly lengthening the service life of tools subjected to this type of treatment – even by 300-400%.

In order to enrich metal surfaces with sulfur, liquid or gaseous hydrogen sulfide is used, sometimes also sodium thiosulfate with the addition of potassium and sodium thiocyanate. Depending on the technology used, the process takes place at a temperature of 200 to max. 900 °C.

Siliconising

This is a method of increasing the resistance to high temperature and increasing the resistance to acid. It takes place by heating metal elements in a powdered ferrosilicon or in a gaseous environment saturated with silicon and chlorine compounds. The temperature needed to achieve the reaction is approx. 1000 °C. Siliconising is a method of chemical heat treating of metals.

Welding

Welding consists of joining metals by means of melting and solidification. Today, there are many different welding methods based on a variety of chemical and physical processes. The most popular methods of electric welding are:

- manual metal arc welding (MMA);

- tungsten inert gas welding (TIG);

- welding with a consumable electrode (MIG/MAG and FCAW);

- submerged arc welding;

- plasma arc welding.

In addition to the above methods, more modern techniques are also used, consisting of welding with lasers, electron beams or electrogas. There are also welding methods in which the heat source is the occurrence of a local chemical reaction. This includes a method used to connect rails, called thermite welding, where a mixture of iron oxide and aluminium is burned.

Useful accessories during welding include all kinds of marking tools, gas cylinders (TIG, MIG/MAG welding), protective helmets and clothes (protecting against sparks and the extremely high temperature).

Powder coating

Powder coating is a very effective way to paint metal surfaces. The process uses electrified powder paint particles with a size of 20-100 micrometres. The bonding is based on electrostatic forces. The technique has many advantages, including perfectly protecting the painted material against corrosion, the lack of harmful solvents and its low price.

Powder coating is widely used in virtually every industry, especially the automotive industry, but also in the production of furniture, various types of machines (agricultural, industrial) and household appliances.

Wet coating

Another widely used technique for coating metal with paint is wet coating. It consists of applying electrostatically charged paint with the use of a solvent, water or a chemical hardener. Various paints are used, e.g. oil, vinyl, epoxy and phthalic paints.

An advantage of this technique is, above all, the attractive finish of the coating and the wide range of available colours. It is also a durable method and protects metal surfaces against rust.

Hot dip galvanisation

An excellent way to protect steel objects against corrosion is hot dip galvanisation. This method consists of immersing pre-cleaned elements in a zinc bath, i.e. molten zinc at a temperature of approx. 450 °C. The process itself usually takes a very short time – up to several minutes.

Galvanisation also enhances the elements’ resistance to mechanical damage. The technique is relatively inexpensive and environmentally friendly. It is commonly used in the production of metal sheets and profiles used in the construction industry, car body parts, tanks, silos, etc., which are exposed to adverse environmental conditions during use.

Recommended tools for metalworking

Choosing the right tools for metalworking depends on many factors. Different tools will be needed in steel mills than in galvanising plants or factories producing car parts. They are usually sophisticated devices enabling very efficient heat and chemical heat treating, as well as mechanical treatment of metals. Industrial equipment includes, among others:

- metallurgical furnaces,

- melting crucibles,

- galvanic baths,

- CNC machines (lathes, milling machines, punching machines, welding machines),

- lasers,

- hammers and rolling mills.

In workshops and for private use, power tools for manual cold processing of metals are used, such as:

- bending machines,

- shrinking/stretching jaws,

- grooving machines,

- cutters,

- wheeling machines,

- holesaws.

Handheld welding machines (MIG/MAG, MMA, TIG) and riveting machines are used for joining metals. Plasma cutters, angle grinders, circular saws and miter saws are used for cutting. They can be used for virtually all types of metal sheets.

The best tool for cutting aluminium, which can be a tricky job at home, is a jigsaw. In industry a concentrated stream of water is used for this purpose.

Metalworking – tools and methods – summary

Without metalworking, civilisation as we know it today would not exist. Metal elements are commonly used due to their ductile properties, endless forming possibilities, as well as durability and resistance to external factors. One of the key advantages is also the ability to conduct electricity, which was important in the creation and development of electronics.

For the above reasons, numerous metal processing methods have been developed. We come across some of them on a daily basis, for example wondering which air impact wrench or grinding machine to choose, while other devices are used in production plants based on complex technological processes (e.g. electron beam welding or laser metal processing).

Share