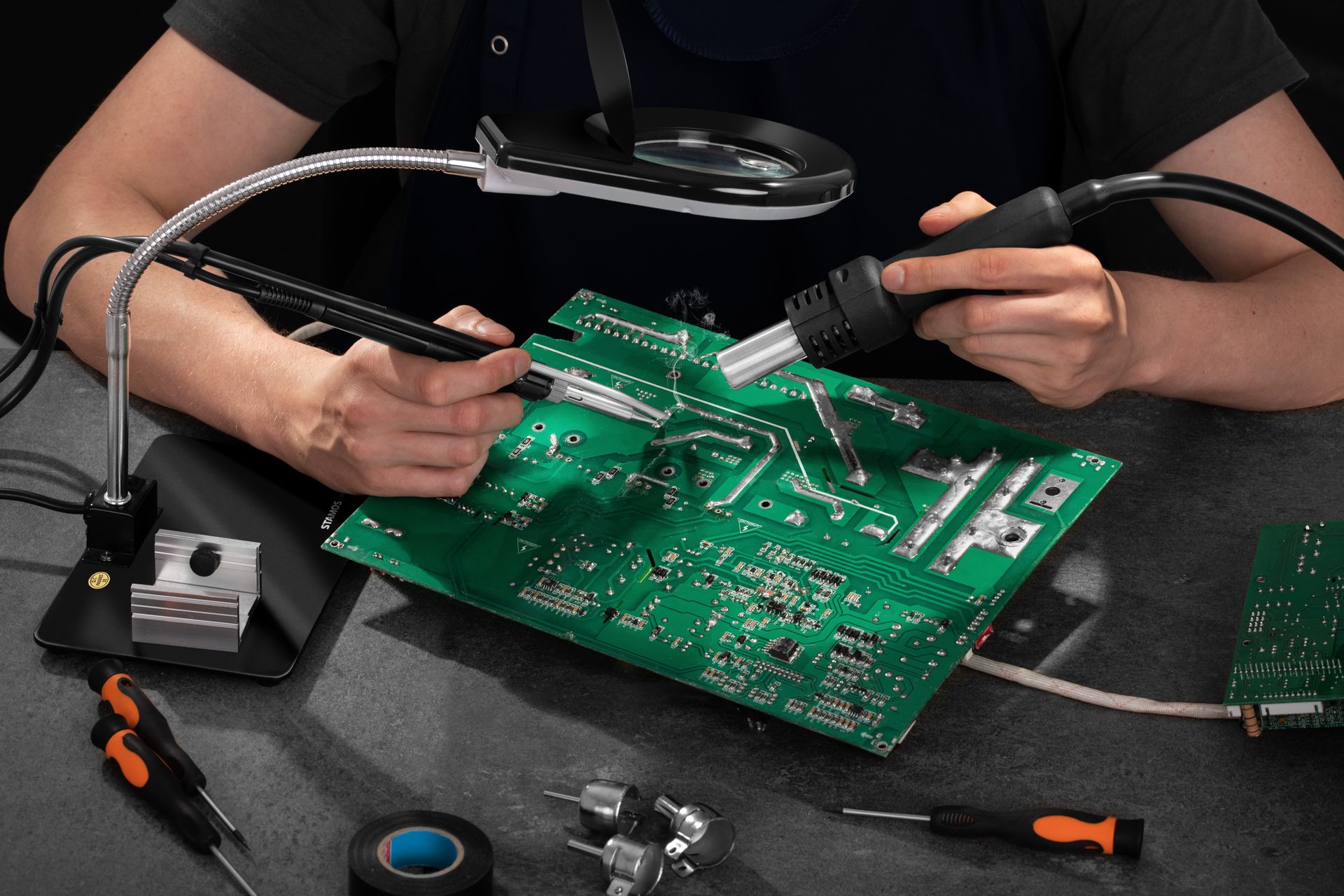

A soldering station is one of the most universal electric tools used by professional electronic technicians, electricians and installers, but also by home DIY enthusiasts. Before buying one, you should consider which soldering station will be the best in your case, and as well the differences between specific models. Read our article and find out basic information on this topic.

A soldering station is one of the most universal electric tools used by professional electronic technicians, electricians and installers, but also by home DIY enthusiasts. Before buying one, you should consider which soldering station will be the best in your case, and as well the differences between specific models. Read our article and find out basic information on this topic.

Features of soldering stations

Soldering stations (sometimes also called soldering irons) are used to bond metal elements using a binder – a solder with a lower temperature than the parts that are to be joined. In the soldering process, the surface of the metals to be bonded is not melted, which is the main difference from welding. The basic feature of soldering stations and soldering itself is the melting point of the solder. Based on this we can distinguish:

- soft soldering (below 450°C)

It usually takes place at a temperature of 250-320°C, and is used in electrical wiring and systems, electronic systems, for connecting roofing sheets, gutters, pipelines and other parts with low stress joints, which need to be firmly connected and have good electrical conductivity. This method is used for soldering steel, copper, zinc and their alloys.

- hard soldering (more than 450°C)

This is used when a connection should be resistant to high temperatures and mechanical damage (e.g. central heating installations with a temperature higher than 110°C). It is usually used for molybdenum, carbon, tungsten and nickel steels, as well as metals such as copper, gold and silver. Propane-butane or acetylene-oxygen burners are used for the brazing process.

With this method, high-temperature soldering, that is above 900°C, is additionally distinguished and sometimes even defined as above 1000°C.

What type of soldering station should you choose?

The basic types of soldering station were presented above, but now let’s take a closer look at soldering stations according to their use and design, and try to find which soldering station or soldering iron itself is suitable for specific jobs.

- heater (resistance) soldering irons

These are the most popular and cheapest type of soldering iron. They have a heater that generates heat and then conducts it to the tip via a wire. The separate power supply makes them very light devices. They are perfect not only for hobbyists, but also general electronic use. Therefore, if you are wondering which soldering iron for electronics will be best for beginners, you should definitely consider a heater soldering iron.

- transformer soldering irons

These are very universal, but operate in a different way. A high current flows through the tip of the soldering iron, creating a high temperature. Transformer soldering irons are equipped with an integrated transformer. An undoubted advantage of such equipment is the quick heating of the tip. They are usually used for soldering electric cables and wires as well as repairing cars. So which transformer soldering iron will be the most practical in your workshop? You should always pay attention to the power of the equipment. Products intended for a wide range of uses come with power adjustment, which allows you to adjust the power to a specific job.

- gas and battery soldering irons

As the name suggests, gas soldering irons are powered by gas, most often propane-butane, making them an excellent alternative if you need to use them in a place without access to electricity. They are good for precise soldering without the need for high power, which can be useful for mobile use. When choosing a gas soldering iron, remember to check the capacity of the gas tank, which too small may not be sufficient for longer periods of work.

Battery operated soldering irons are equally light and handy, and they also have a low power output, so they are usually used for minor repair works on small parts. The purchase of batteries can generate additional operating costs, so they are a better choice as handy tools for small jobs.

- soldering stations

Soldering stations are the most extensive type of soldering equipment. They consist of a soldering iron and a control panel, and sometimes also come with an absorption pipe or a lamp with a magnifying glass. They have power and temperature adjustment, letting you precisely adjust them to your requirements.

- hot air soldering stations

If you are wondering which soldering station will be the most universal in your case, consider models with hot air soldering irons. This specific type is perfect for soldering and desoldering surface-mount devices (SMD). However, this is not their only feature, as they are also used for drying paint, removing adhesives, warming, defrosting, shrinking heat-sealable foil, etc.

Which soldering station should you buy for different uses?

When choosing a soldering station you should first of all think about your needs. There is no easy answer to the question which soldering station you should choose. Only after specifying your needs and expectations will you be able to narrow down your options. Whether you intend to use it at home or for professional use is of great importance. DIY enthusiasts who do odd jobs around the house from time to time will have different needs, for example, than technicians in electronics companies.

The price is also an important part of the decision making process. The simplest stations, with a basic range of functions, can be purchased for around fifty pounds, while professional equipment, with the possibility to adjust most of the parameters, can cost as much as nearly a thousand pounds. Such expensive models usually have additional elements, such as an infrared lamp and a heating plate, and are suitable for a wide range of uses: soldering/desoldering of BGA, SOIC, CHIP, QFP, PLCC, SMD and IC components, repairing computer motherboards, etc.

Which soldering station should you choose for an electrical company?

When putting together a list of basic equipment for a company operating in the electrical industry, you should first analyse which tools you will need. A soldering station will definitely be on the list, due to the need to frequently connect the wires.

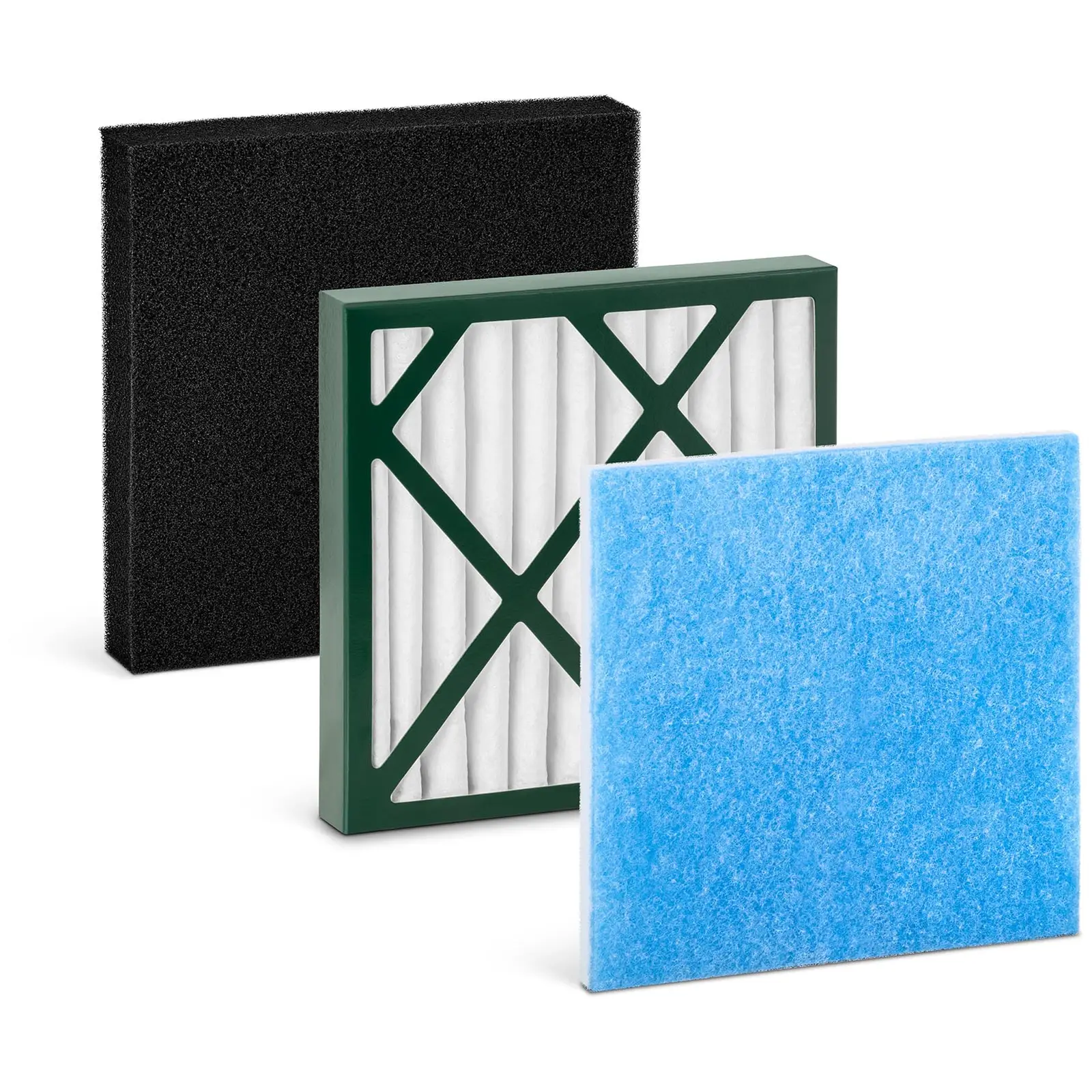

In addition to adjustment options and a clear display panel (preferably equipped with an LCD or LED display), it should also be safe and comfortable use, even for lengthy periods of time. Therefore, when preparing your work stations, you should have a fume absorber for harmful soldering fumes.

Which soldering station should you choose – summary

Which soldering station you should choose depends on your needs. The main distinction regarding the soldering technique (soft and hard) is the available temperature range, as well as where it will be used. For home use, low-performance equipment will be suitable for simple tasks. Professional use, however, requires considerable efficiency and the possibility of adjusting the most important parameters depending on your specific needs for a given job. Soldering stations are used by workers in various industries. Electronic technicians, electricians (including car electricians) and installation fitters use equipment that combines high precision, efficiency and work comfort on a daily basis. Therefore, if you are thinking about starting your own business, you should definitely consider purchasing professional tools. Read our other articles and find out, among others, how to set up a construction company.

Share