Just like in a workshop or on a construction site, with welding safety is the main priority! There is a range of protective items and clothing you should wear, depending on the type of welding you will be doing. The heat emitted during welding is particularly dangerous, which, combined with extremely bright sparks, poses a great risk if you are poorly protected. Below are some welding accessories that you should definitely consider.

Just like in a workshop or on a construction site, with welding safety is the main priority! There is a range of protective items and clothing you should wear, depending on the type of welding you will be doing. The heat emitted during welding is particularly dangerous, which, combined with extremely bright sparks, poses a great risk if you are poorly protected. Below are some welding accessories that you should definitely consider.

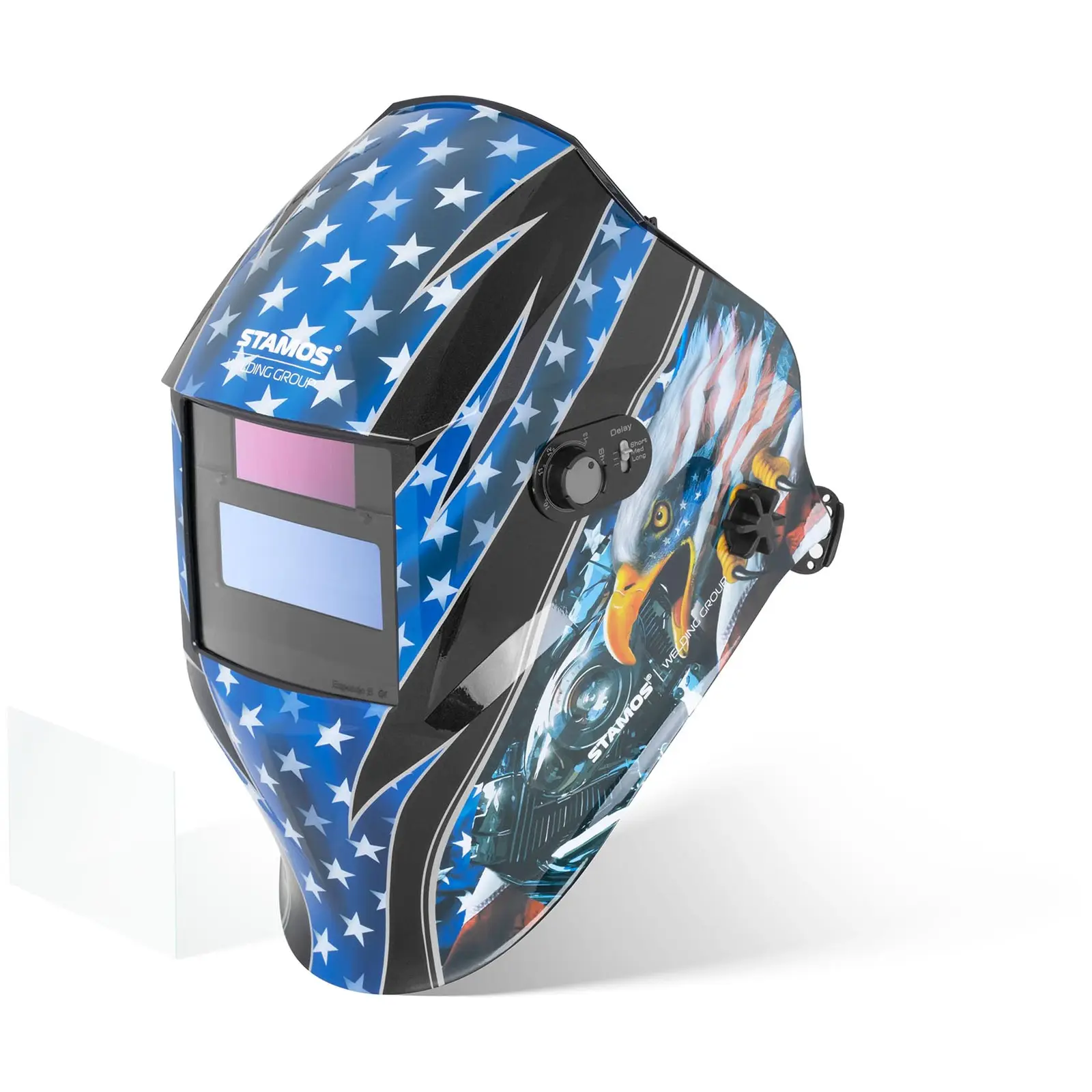

A welding shield – an absolute must for every welder

It doesn’t matter whether you are using electrodes or welding with the MIG/MAG or TIG method. Welding sparks are too bright to for you to look at them without protection. This carries a risk of serious eyesight issues, which is why welding must never be carried out without a shield or a suitable helmet. Anyone helping you weld should also wear a welding shield or a mask during welding. A welding helmet will also be very useful, although even the best welding helmet will significantly restrict your movement, and wearing one can be very tiring in the long run. That’s why a welding shield is the most useful protection item for professional welders.

A welding shield – the most important piece of welding equipment

Due to their protective properties, welding shields meet all applicable safety standards. The best shields have a shade level range from DIN 9 to DIN 13. In order for the field of view to be darkened quickly enough after the arc is struck, the response time of the shield should not be more than 1/25000 s. Only in this way will your eyes be properly protected. Stopping the welding process automatically causes the visor to brighten again, with a slight delay of 0.25 to 0.8 seconds. This allows you more time for your eyes to adjust to the surrounding light. A smooth dimming and brightening process will enable safe and precise welding. Other properties worth paying attention to are the optical class, light diffusion, luminous transmittance variation and angle dependence. You can feel safe using a shield if the optical grade values for the above properties are 1 or at least 2.

Safe welding with a welding shield

The shield should be held as close as possible to the arc in order to have full control over the quality of the weld. Welding shields not only protect against extreme temperatures, but also welding spatter, which could otherwise cause burns to your face. Additionally you can wear a welding hood, protecting your neck and chest. This hood is worn just below the welding shield.

Make sure the welding shield fits the shape of your head well. For longer welding jobs, a well-fitting helmet is essential to prevent head muscle fatigue. During sanding work, the GRIND function comes in useful, allowing you to disable automatic dimming. When eye protection is no longer needed, opening the shield should be easy.

Welding gloves – make sure they match the size of your hands

Welding gloves protect against sparks and extreme temperatures. Contact with hot objects is inevitable. However, using welding gloves you can forget about the risk of such burns. As a rule, gloves for welding are made of cow split leather and sewn together with KEVLAR threads. These materials are resistant to extremely high temperatures.

When wearing welding gloves, make sure you use the torch carefully when guiding the electrode along the metal you are welding. Also change the equipment settings so that you always get the best welding properties. For this purpose, comfortable, five-finger welding gloves are best, providing sufficient freedom of movement. When choosing welding equipment, make sure you can use it wearing protective gloves. After all, you don’t want to take them off while welding. Welding accessories enabling you to rotate the metal you are welding will also make your life much easier.

You often need to do additional work on the welds. In order to check their quality, you should remove the slag or polish the weld with a fillet weld grinder. Again, the welding gloves should allow sufficient freedom of movement, so that you can carry out all necessary activities without taking them off.

Welding aprons (depending on your needs)

Welding aprons protect your upper body during welding. The leather that the aprons are made of (usually cow split leather) should protect against sparks generated during cuts and the high temperatures of surrounding objects. Try the apron on and make sure that the welding gloves cover the sleeves and cuffs.

Welding aprons are especially useful for longer jobs. They should also allow freedom of movement, so as not to restrict your movements when working in unusual positions. Velcro fasteners make it much easier to put the apron on. They can also be opened quickly, making it easier to quickly access tools or items inside the pockets.

The welding apron is a simple but effective alternative to a welding jacket, providing protection for easier, less risky jobs. They are also much more comfortable, especially at very high temperatures.

Protect your surroundings

Besides yourself, you should also protect the surrounding area. Passers-by and colleagues are also exposed to the very bright light during welding. Even strong sparks can cause skin burns. Remember to keep all flammable substances away from the workpiece you are welding.

Welding walls can provide effective protection when positioned around your workplace. The material used for such walls is extremely resistant to heat and fire. The walls usually have wheels, making it easy to move them around as necessary.

Ensure a safe workplace for both yourself and others. Regardless of whether you are using an aluminium welder, plasma cutter or an electrode welder, basic safety equipment, such as a welding shield, gloves and at least one welding apron, should be on your must-have list of protective clothing.

Share