A pellet machine (also known as a pelletiser) is used to produce pellets. The pellets are usually produced from wood, straw or sawdust and pressed under high pressure. You can use them as fuel for your pellet furnace or as animal feed. From our article, you will learn how to properly service and operate the Wiesenfield WIE-PM-3000 pellet making machine.

A pellet machine (also known as a pelletiser) is used to produce pellets. The pellets are usually produced from wood, straw or sawdust and pressed under high pressure. You can use them as fuel for your pellet furnace or as animal feed. From our article, you will learn how to properly service and operate the Wiesenfield WIE-PM-3000 pellet making machine.

How does a pellet machine work?

A pelletiser converts biomass, such as sawdust, into pellets in an efficient manner. Once the feedstock is poured into the hopper, it is compressed by a die inside the machine. The process takes place at a high pressure and a temperature of 60 to 80°C, which ensures an optimal pellet consistency. Its size depends on the die used. The diameter of its holes translates into the size of the pellets obtained.

How to use the Wiesenfield WIE-PM-3000 pelletiser

WATCH THE VIDEO ON HOW TO USE THE WIESENFIELD WIE-PM-3000 PELLET MACHINE!

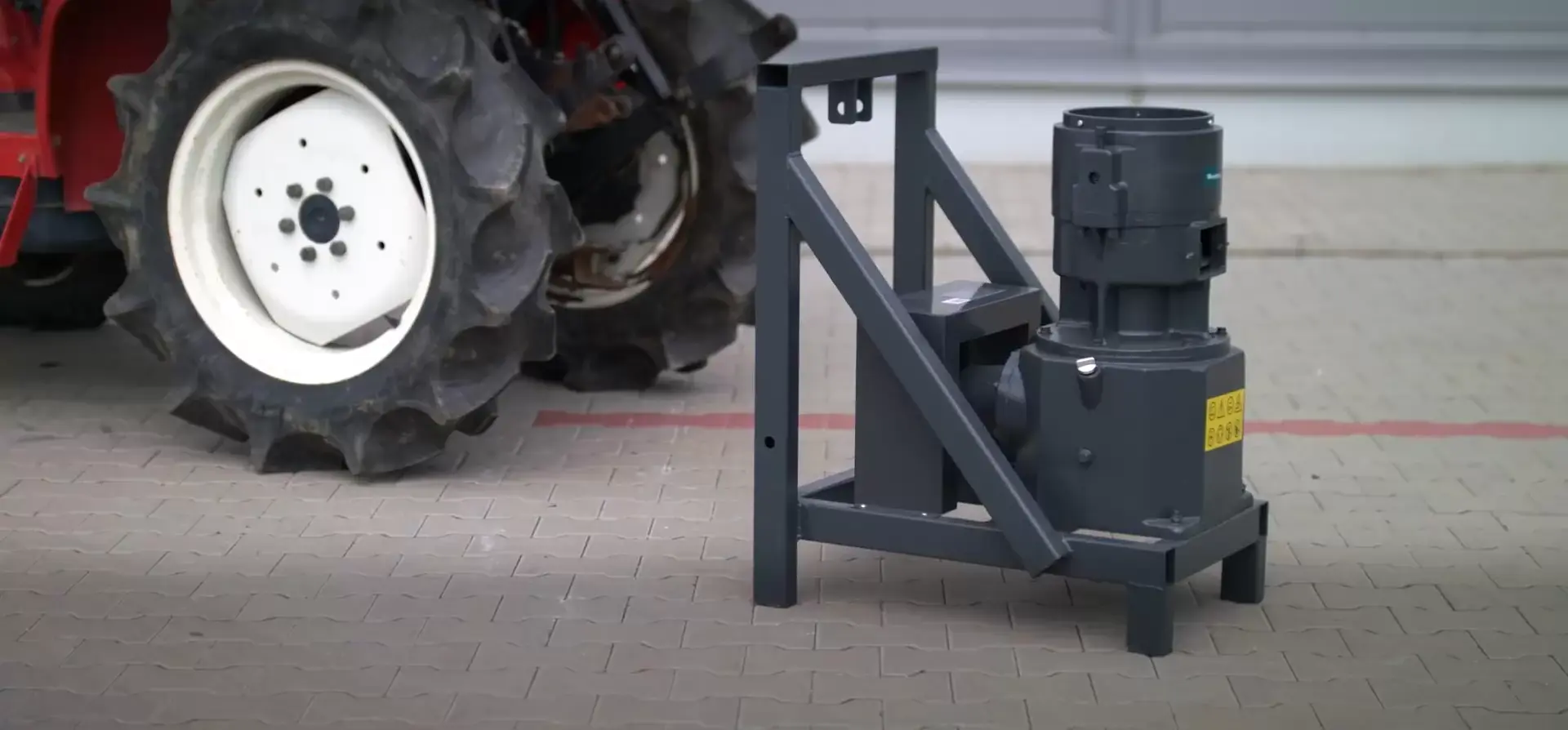

Pelletiser Wiesenfield WIE-PM-3000

- Versatile – for the production of pellets from organic materials for heating and fertilising and feed for animals

- Efficiency – processes 300-400 kg/h of feed or 130-180 kg/h of wooden sawdust

- High power – powered by a power take-off connected to the tractor (15-28 hp)

- Durability – excellent pellet consistency thanks to an operating temperature of 60 to 80°C

- Intuitive – compact, mobile and easy to use machine

Pelletiser Wiesenfield WIE-PM-3000 – machine overview

ATTENTION: This article is intended as a guide to facilitate the use of the device. Before you start working, be sure to read the manual and the safety instructions contained in it!

Take a close look at all the components that the pellet making machine is made of:

- Hopper

- Tractor hitch mount

- PTO drive shaft

- Hole for tractor hitch

- Frame

- Gearbox

- Chute

- Upper casing

Pelletiser Wiesenfield WIE-PM-3000 – assembly of the device

Once you have unpacked your pellet machine, follow the steps below:

- Attach the net to the hopper.

- Place the hopper on the machine casing and screw in place.

- Screw the chute on as well.

- Screw one end of the drive shaft to the machine.

- To connect the machine to the tractor, place the catches in the holes (4).

- Use the catches and the handle (2) to attach the machine.

- Connect the other end of the drive shaft to the tractor.

How do I prepare the Wiesenfield WIE-PM-3000 for operation?

- Place the pelletiser in a safe, clean, stable place (away from heat and water) to ensure airflow.

- Check that all screws and bolts are tight.

- Disassemble the rollers and remove the bearings.

- Grease the bearings and assemble the rollers.

- Press in the grease using the supplied grease gun. Place the end of the grease gun in the grease injection hole. 6.

- Remember to lubricate the bearings with grease intended for this purpose.

- Repeat this operation after every 8 hours of operation of the pellet machine.

- Adjust the rollers to ensure free movement of the die.

How do I grind the die before first use?

Remember to prepare the machine correctly before grinding the die (see above)!

- To grind a new die you need:

- 5 kg of sawdust (sawdust or flour),

- 1.5 l of vegetable oil (can be used or dirty),

- 5 kg of fine sand (optional).

- Start the tractor to which the drive shaft of the machine is attached. The die will start to rotate.

- Place the granular container under the chute.

- Mix all the ingredients in the bucket until a smooth consistency is achieved. Run it through the die 80-90 times until the granulate meets the quality requirements.

How to start the Wiesenfield WIE-PM-3000 pellet machine – operating guide

Once you have the device ready to go and the die grinded, you can proceed. Take the following steps one at a time:

- Prepare the mixture for pellet production – the maximum length of raw material should be about 5 mm.

- Start the tractor to which the drive shaft of the machine is attached. The die will start to rotate.

- Place the pellet container under the chute.

- Pour a small amount of the mixture to be granulated into the hopper. If you throw in too large of a portion at once, the die may clog.

- Follow the same procedure until the prepared mix has been completely processed.

- When you have finished working, switch off the machine by stopping the tractor.

- Remember not to stop the machine while the pellets are being pressed (except for an emergency stop)! The machine may jam.

- Clean the machine so that no pellets are left on the rollers or in the die.

- Bear in mind that the pellets will reach the correct consistency only after they have cooled down.

Servicing the Wiesenfield WIE-PM-3000 step by step

Always ensure that the pelletiser is not connected to the drive before carrying out maintenance.

Replacement/disassembly of the die

- Turn off the tractor to stop the drive shaft of the machine. Disconnect the drive shaft from the tractor.

- Unscrew the hopper and remove it from the casing.

- Remove the screws adjusting the pressure between the die and the rollers and the screws securing the upper casing. Pull out the rollers.

- You can use a drill to pre-push the holes in the die.

- Clean up any remaining material.

- Remove the locking device of the retaining nut.

- Loosen the clamping nut using the spanner provided.

- When you remove the clamping nut, you will see the holes for attaching the holder.

- To remove the die, first screw the holder in with the two screws. Then slowly screw in screw 3, then the die will start to lift gently.

- Pull out the die.

- Clean the rollers of any remaining material.

- Clean or replace the die with a new one – remember to use only non-corrosive cleaning agents.

- Thoroughly dry components after each cleaning.

- When assembling, repeat the previous steps in reverse order.

Roller and die lubrication

Lubricate the rollers and the die with bearing grease after every 8 hours of operation.

- Dismantle the hopper.

- Remove and dismantle the rollers.

- Remove bearings.

- Grease bearings.

- Twist rollers and install on die.

- Insert and tighten screws.

- Force grease into the die using the supplied grease gun.

- Insert the tip of the grease gun into the grease injection hole.

- Press on the handle of the grease gun to start the injection.

Oil change

Remember to change the oil after 60 hours of operation.

- Place the used oil container in a suitable place.

- Loosen the screw (marked “b”).

- Wait for the oil to drain.

- Tighten screw “b”.

- To pour fresh oil into the box, unscrew the oil filler marked “a”. Pour in the oil and then screw the filler cap on.

- Measure the oil level and condition with the detachable dipstick.

Share