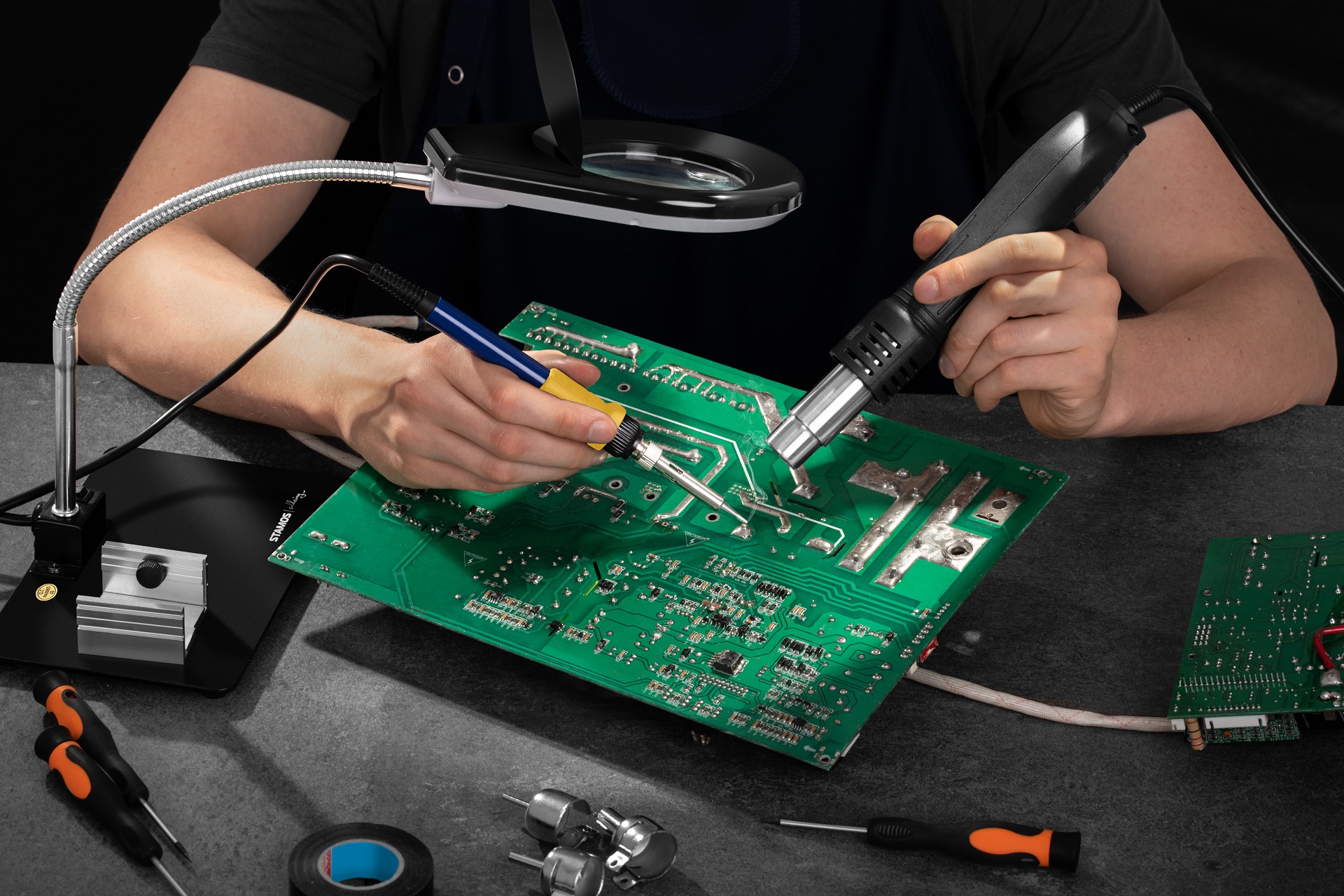

Doing odd jobs around the house often means we need to do things usually reserved for professionals. If you don't want to hire a specialist or none are currently available, but urgent jobs need to be done, then you can try to learn how to do these jobs yourself. One such job, for example, could be joining together metal elements during the maintenance of gutters, heating systems, electrical installations or water and sewage systems. In such cases, soldering may be necessary, also in the case of repairing electronic appliances and some construction works. In our guide, we discuss different types of soldering, as well as how to effectively solder specific materials (aluminium, copper, etc.).

Doing odd jobs around the house often means we need to do things usually reserved for professionals. If you don’t want to hire a specialist or none are currently available, but urgent jobs need to be done, then you can try to learn how to do these jobs yourself. One such job, for example, could be joining together metal elements during the maintenance of gutters, heating systems, electrical installations or water and sewage systems. In such cases, soldering may be necessary, also in the case of repairing electronic appliances and some construction works. In our guide, we discuss different types of soldering, as well as how to effectively solder specific materials (aluminium, copper, etc.).

Welding and soldering

Before we get into the details, it is worth emphasising that there are two main ways to join metal together. The first is welding, in which the joined elements are fused so that they fit together. This type of connection is called a weld. There are various welding methods depending on the materials to be joined, as well as where the processing takes place.

The soldering process is very different, and consists of using a binder. Soldering does not interfere with the condition of the joined elements, but only melt the binder that fills the space between the surfaces of these elements. A undeniable advantage of soldering is that it requires much lower temperatures than in the case of welding.

As with welding, soldering can also be done in different ways. In addition to the division into flux soldering, flux-free soldering, mechanical oxide removal soldering, reaction soldering and diffusion soldering, soldering can also be divided into brazing and soft soldering, and it is this division that we will be looking at in this guide. What exactly are they and how do they differ from each other? Let’s have a closer look.

Brazing

This method of soldering requires a melting point of the filler of more than 450 degrees Celsius. Silver solder, phosphorus solder or copper solder are used in brazing. Brazing is performed using induction soldering irons, oxygen-acetylene burners, soldering lamps or propane-butane burners. This is how carbon steel, copper, gold, silver, brass, bronze, chrome and nickel steel or sintered carbide are soldered.

Brazing is a method that is often used in the construction or maintenance of heating, cooling and air conditioning systems. Brazing ensures a high level of durability, as the joints formed this way are resistant to temperatures reaching 100 degrees Celsius, as well as to stretching and mechanical damage. However, remember that brazing should only be used in well-ventilated rooms, due to the harmful gases that are released during processing.

Soft soldering

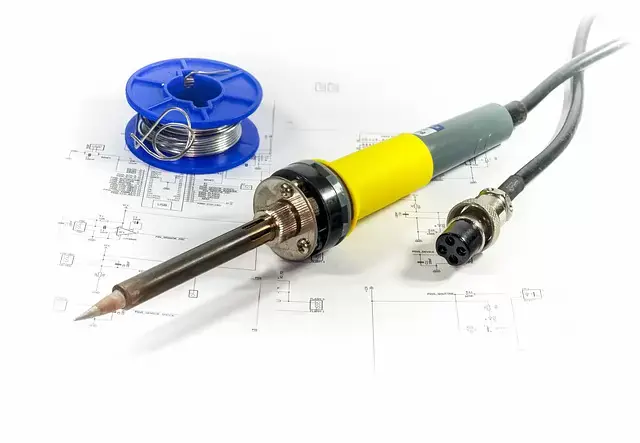

The situation is very different in the case of soft soldering, where the temperature during material binding is less than 450 degrees Celsius. The binder is made of tin-copper or tin-lead solders in the form of wire or special sticks.

They are commonly used in electronics due to the fact that they are excellent conductors of electricity, as well as the relatively low temperatures at which soft welding takes place. Soft soldering can also be a good option when working on water supplies and other systems, if the operating temperature does not exceed 110 degrees Celsius.

Soldering aluminium

Aluminium is actually the name of a chemical element. All kinds of objects, home appliances, or even bicycle frames, although commonly called aluminium, are in fact made of aluminium alloys with other elements. For many years, heat treating aluminium was impossible due to the fact that there was no suitable solder.

Fortunately, this changed some time ago and it can now be bought relatively easily. Such solders are aluminium with the addition of silicon. Soldering aluminium has therefore become quite common. However, to do this you will need a suitable propane-butane burner, with which to bond the aluminium elements. You will also need appropriate tools, such as welding tongs, to hold the joined pieces of aluminium together.

Then all you need to do is properly heat up the pieces to be bonded together, to a temperature that exceeds the melting point of the solder. The heating time depends on the size of the joined elements. The larger they are, the longer it will take to heat them up. You will therefore need to use a larger flame in the burner. People with some experience could use burner sets, e.g. a large burner with a large flame for preheating and a smaller burner for heating the place to be soldered.

Soldering copper

Copper works great in the production of pipes for plumbing, gas, air conditioning, etc. Copper pipes are corrosion-resistant, easy to connect, and have bactericidal and fungicidal properties. They are therefore durable and protect against diseases from water pollution. Connecting aluminium pipes, as well as maintenance by soldering holes in the event of damage, can be carried out in two ways.

One of them is soft soldering. In this case, bonding copper elements can be done using a strong soldering iron, heat gun or a small burner that lets you use a temperature not exceeding 450 degrees Celsius. In the case of brazing, more efficient equipment will be required. You will need a propane-butane burner, an acetylene burner, or a MAP gas burner.

However, depending on the type of installation, you should bear in mind that when using a propane butane burner, heat treatment will introduce pollutants into the air. So, if you want to build a drinking water supply, it is better not to use this type of burner. The binder used for copper soldering is copper or tin solder.

Soldering brass

Brass, thanks to its physical and chemical properties, has a very wide range of applications. Unfortunately, brass elements very often get cracked or damaged in other ways. Of course, brass can be soldered, but for the joints to be of good quality, you need to know the physical and chemical properties of both the parts to be joined and the solder.

Let’s start with the fact that brass can be double-component – copper and zinc, or multi-component – zinc and tin, lead, manganese. Before you start soldering, you should know the exact composition of the brass elements. Special markings come in handy here. The chemical composition is as follows:

- In the case of double-component alloys, i.e. alloys containing zinc and copper, they are marked with the letter “L” and a number. As the percentage of each of these components may vary, the number tells us the percentage of copper in the brass. For example – L85 means that you are dealing with an alloy of 85% copper and 15% zinc.

- In the case of multi-component alloys, two-letter and two-digit markings are used. For example, the symbol LA77-2 means that the alloy contains 77% copper, 21% zinc and 2% aluminium.

Regardless of the type, brass has high anti-corrosion properties and is of adequate strength. However, for good quality soldering you should select the correct solder according to the type of brass. For example, when it comes to bonding brass components with a predominant percentage of copper content, then silver soldering should be used, i.e. a solder that contains a large percentage of silver (PSr12 or PSr72).

In the case of brass with a high zinc content, a PSr40 solder would be a good idea. The key to a durable and solid connection will therefore be to determine the melting point of the parts to be soldered, and choose the thermal expansion coefficient. You should also remember that the brass and the solder should form a galvanic pair. If this does not happen, it will most certainly lead to corrosion.

For soldering brass, a soldering iron with a power of not less than 1000W should be used. Such a device will provide the right temperature to properly heat up the soldered elements and the solder itself. Typically this should be 500 degrees Celsius, allowing for brazing. Of course, soft soldering is also possible, but only if the brass has a high copper content.

According to many specialists, soldering brass is most convenient with devices such as soldering stations. These usually have a temperature control function, which allows you to precisely determine the optimal heating mode.

Soldering silver

Before starting any work on soldering silver, you should also check the composition of the soldered elements. Although the melting point of silver is 960 degrees Celsius, there are hardly any objects made of its pure form. Therefore, the melting point of the alloy depends on its components. If you want to solder silver yourself, you can buy refractory solder with a safe melting point of 240 degrees, typical for PS-2 and PS-2.5. However, due to the high value of silver, we would recommend going to a jewelry shop for any repairs.

Brazing and soft soldering – summary

So, as you can see, choosing the soldering method depends largely on the type of metal you want to connect. When choosing brazing or soft soldering, you should also choose the right equipment, allowing you to heat the bonded elements and the solder to the right temperature. In many cases, such as silver soldering or brass soldering, it is important to carefully understand the percentage composition of the metals that make up their alloys.

Share